ThoraCic/LUMBAR/SACRAL

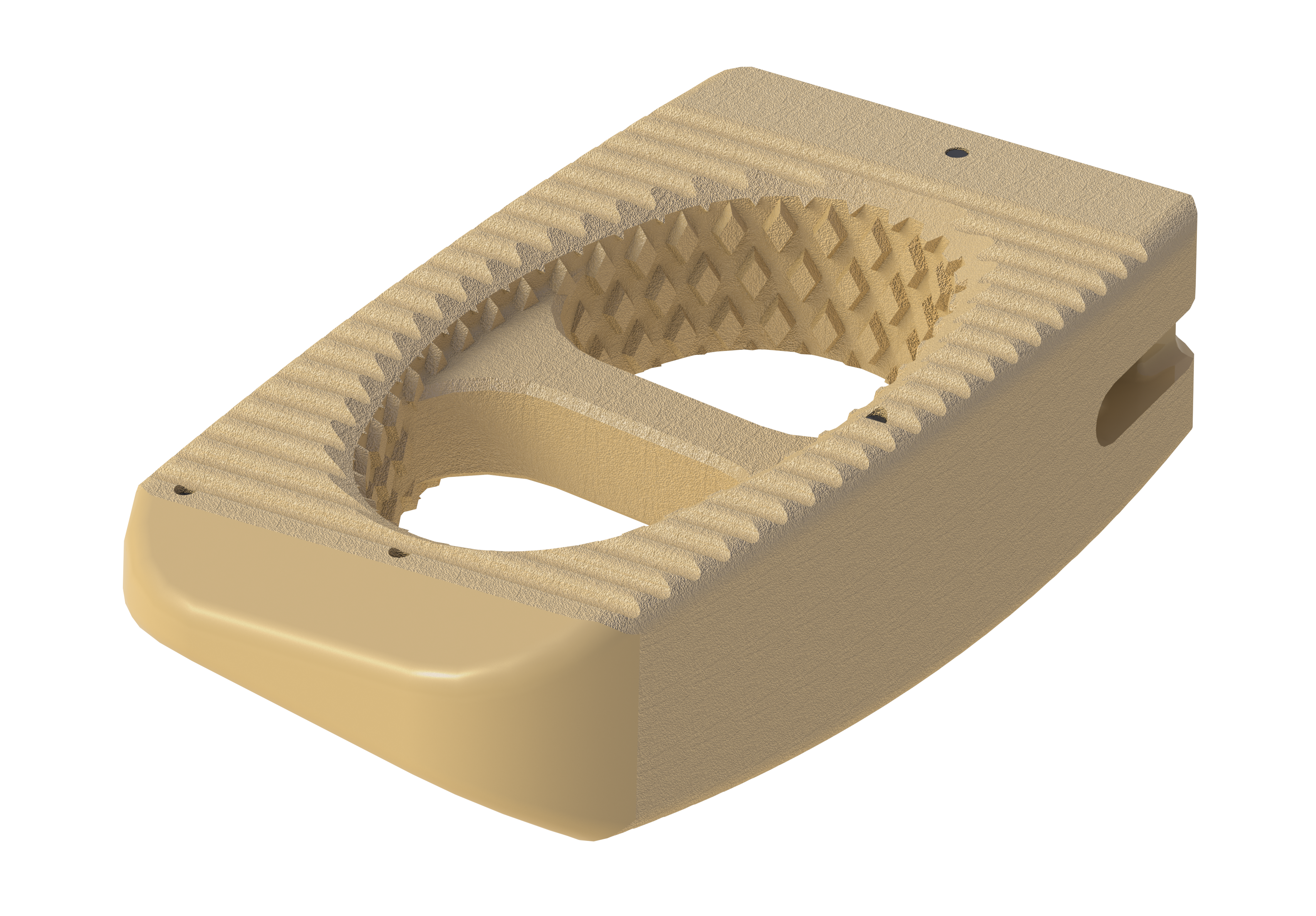

Lumbar Implants

- Designed, developed, and manufactured with 3D printing partner

- Near-net shape 3D printed surfaces with precision machined instrument connection features

- Full portfolio of shapes and sizes to meet anatomic approach and fitment for cervical and lumbar spine

- Printed PEKK polymer is designed to participate in bone growth without compromising the radiolucency of traditional PEEK

- Developed fixturing to hold the irregularities of the 3D printed blanks for final machining.

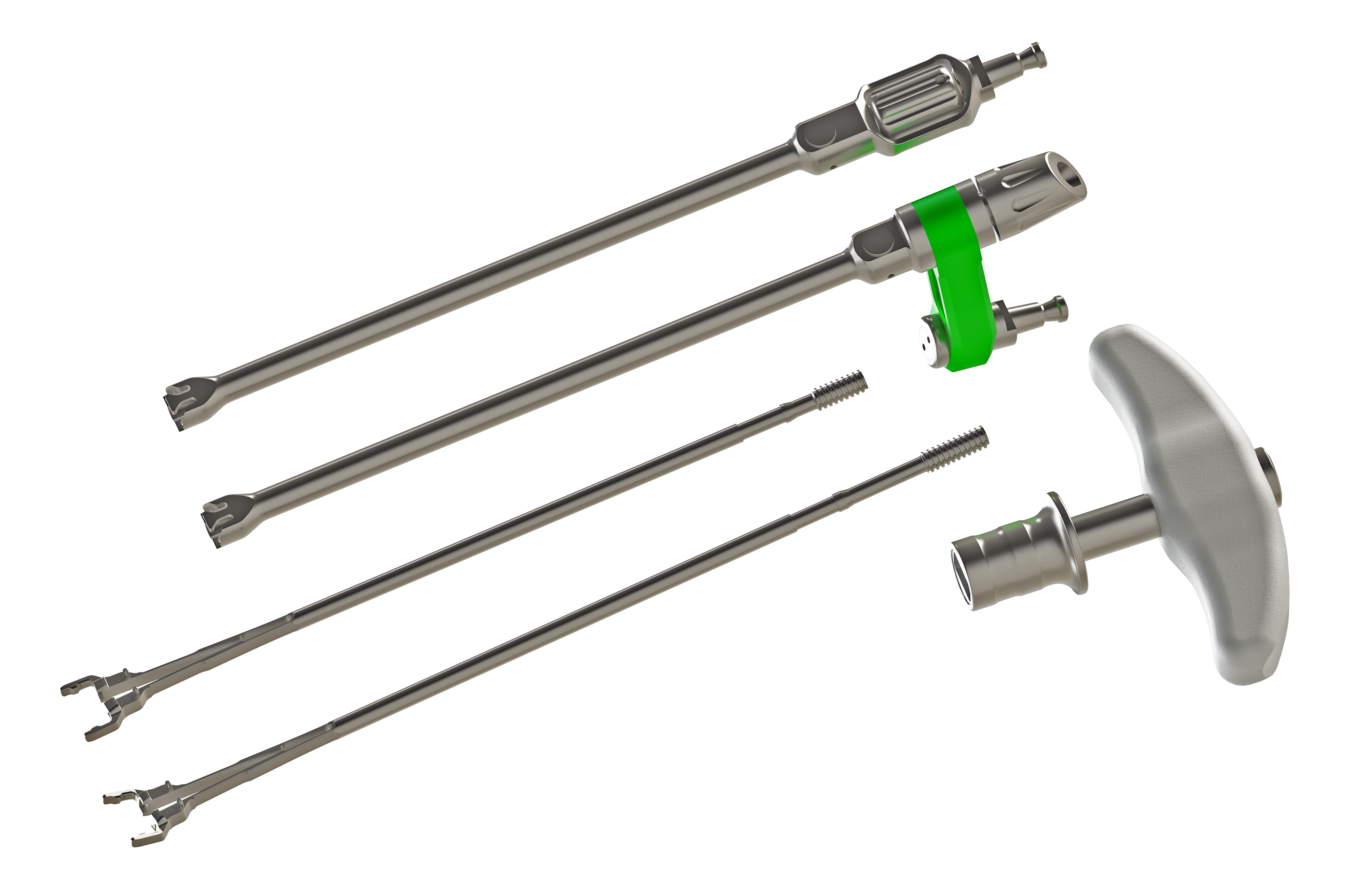

Inserters

- Fully designed, developed, and manufactured in-house

- Feature patented clamping technology to securely hold IBF implants during insertion and manipulation

- Custom designed interfaces for each of the families to optimize impaction load distribution during implantation

Inserters with Screws

- Cleanable screwdriver. Lock and unlock feature allows to disassemble the screwdriver for easy cleaning and reprocessing.

- Screwdriver was designed, developed, and manufactured in-house.

- Compliant screwdriver that meets ISO standards for reprocessing.

- Standard T-25 Hexalobe Drive with a ¼” square drive quick connection

Lumbar Rapid Reducer

Sleek rod reduction design with multiple function with a ball screw design using ceramic bearings reducing instrument friction and providing maximum mechanical advantage for rod reduction. One Instrument designed to facilitate:

- Rapid rod reduction, up to 25mm with just two handle rotations

- Set screw insertion and final tightening through rapid reducer

Segmental deformity de-rotation

Lateral Retractor

Lateral retractor system was designed, developed, and manufactured in-house.

-

- State of the art retractor system when it was introduced in 2010

- Retractor allows for both 4-blade and 2-blade technique

- Individual blade retraction and articulation

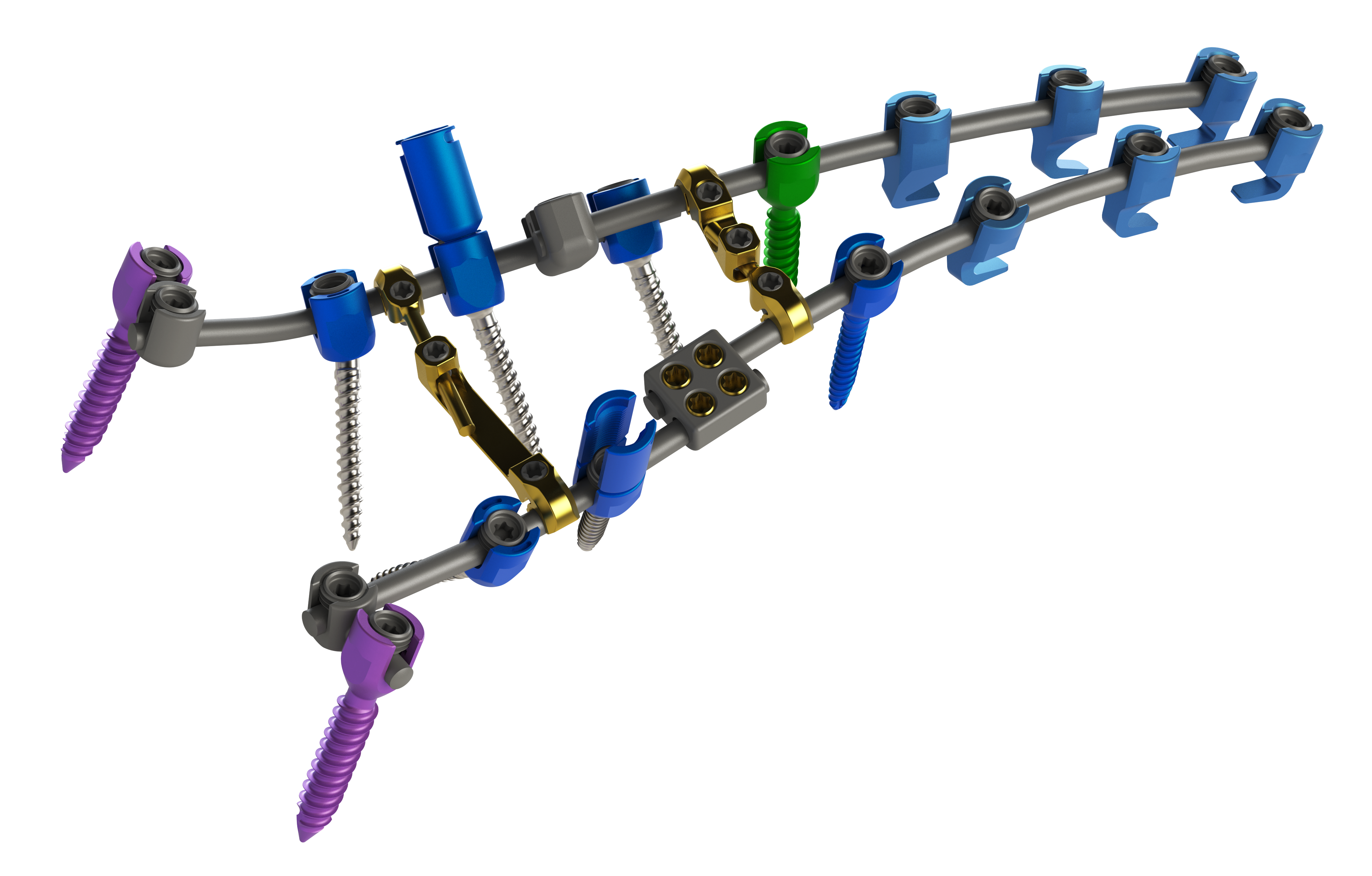

Degenerative and Deformity Systems

- Fully designed, developed, and manufactured in-house

- Consists of poly-axial screws, poly-axial reduction screws, fixed (mono) screws, lateral offsets, inline and offset connectors, and fixed/variable crosslinks

- Best-in-class extreme 60° conical screw angulation achieved to meet unique requirements for the posterior thoracolumbar and lumbar spin

- Intuitive and patented instrumentation developed to bridge the compromise in surgical technique from traditional pedicle screw design

- Streamline instrumentation to include minimal instruments that reduces the steps required to perform the traditional procedure. One set screw used for all implants that utilizes the same T-25 Hexalobe drive mechanism for all devices.

Anterior Lumbar Plate System

- Implant was designed, developed, and manufactured in-house.

- Unique bone screw design with integrated set screw that locked the screw angle relative to the plate.

- System included both lumbar and sacral plates.

Collaborate With us

We are always looking for new opportunities to collaborate and innovate with external partners to help improve patient lives. If your company is looking for a partner to accelerate innovation and speed to revenue, please fill out the following form. Do not submit confidential or proprietary information through this form.